Sea Ray 420 Sundancer

Sol Mates

Full Enclosure, Dockside Decking, Cockpit Carpeting – Sea ray Sundancer

Aft Cover

Cruisers Yachts Full Bridge Enclosure and Aft Panels

Rigid Enclosure

Sea Ray Sundancer 460 Hardtop

We created five custom forward semi-rigid windows for this Sea Ray 460 Hardtop this summer. These windows flip up and attach to the hard top with a fastener. It allows the windows to stay up, but for extreme airflow if needed while out on the water.

For this forward enclosure, we used Tuffak (Markolon) polycarbonate for the window materials. Polycarbonate is a semi-rigid material, that is more stiff then Strataglass. Tuffak does not shrink or stretch in the sun, it stays the same size. This ensures that your canvas will always fit as perfectly as it did on the first day of install.

For the fabric the customer chose Sunbrella for their new enclosure. This fabric has a 10 year warranty. It is fade resistant and lasts while exposed to harsh weather elements. Sunbrella helps provide good protection from the sun. You can enjoy long hours out on your boat. It is breathable and allows air to pass through it. Sunbrella fabrics are also mold and mildew resistant. If exposure to certain debris cause this to happen, it can easily be cleaned with a simple bleach solution, without the canvas loosing its color.

We used SolarFix thread for these windows. SolarFix is a PTFE (PolyTetraFlouroEthylene) thread because of what it is made out of it has a lifetime guarantee. It is UV resistant and resistant to chemicals too, so this means that this customer will never need any re-stitching repairs. For zippers we used Lenzip plastic molded zippers which also have a life time guarantee on them. Here at Chicago Marine Canvas, we suggest you allow us to use the highest quality materials, that way your new cover, stays new for a long time, and you never need to get repairs!

We used SolarFix thread for these windows. SolarFix is a PTFE (PolyTetraFlouroEthylene) thread because of what it is made out of it has a lifetime guarantee. It is UV resistant and resistant to chemicals too, so this means that this customer will never need any re-stitching repairs. For zippers we used Lenzip plastic molded zippers which also have a life time guarantee on them. Here at Chicago Marine Canvas, we suggest you allow us to use the highest quality materials, that way your new cover, stays new for a long time, and you never need to get repairs!

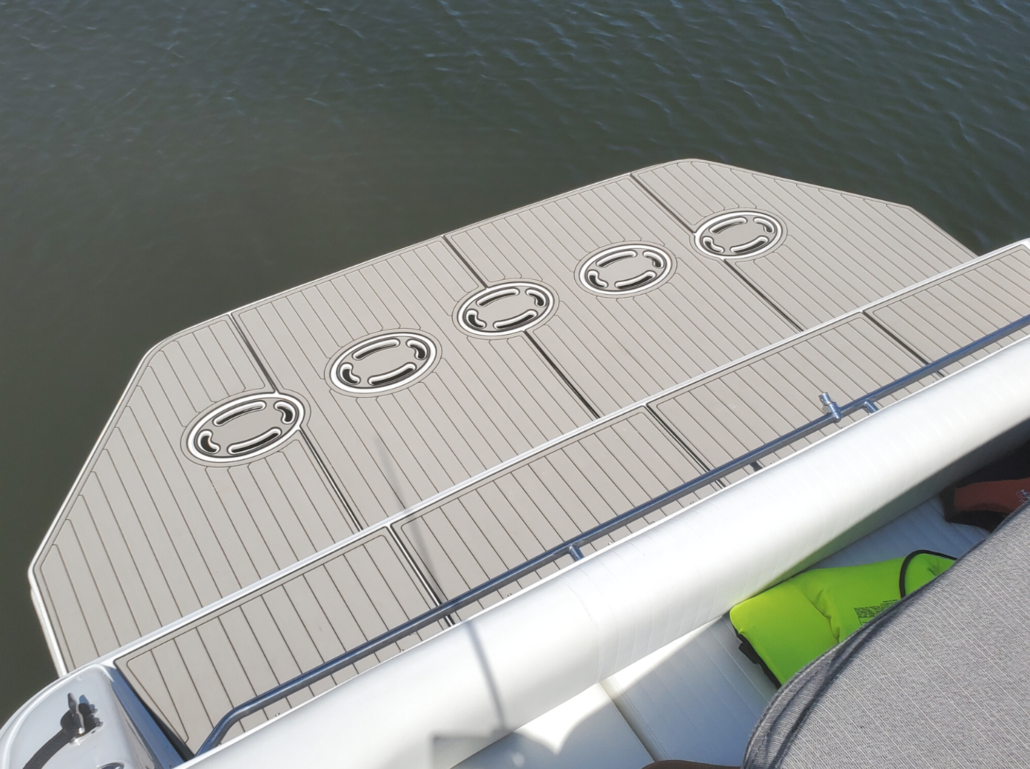

Dingy Cover For Galeon 560 Skydeck

This 2017 Galeon 560 Yacht needed a new dingy cover.

This 2017 Galeon 560 Yacht needed a new dingy cover.

Here at Chicago Marine Canvas we specialize in custom covers therefore, none of our covers are the same. They are all different to ensure that each one fits the boat in need properly. We also use many labor-saving tools that help us do things quickly. This saves you money at the end of the day on the perfect cover.

The first step to our process is to head out to your boat to take measurements with our 3D measuring device. After we gather precise measurements we head back to the shop to start our design process on the computer. We do all of our design work using CAD (Computer-Aided-Design) Software. Because we are working on the computer we can see exactly what we are creating in 3D. This allows us to create the perfect fitting cover for your boat. After the cover is designed, we draw it out using our plotter. This draws out all the pieces of the pattern perfectly so our seamstress can sew it up!

The first step to our process is to head out to your boat to take measurements with our 3D measuring device. After we gather precise measurements we head back to the shop to start our design process on the computer. We do all of our design work using CAD (Computer-Aided-Design) Software. Because we are working on the computer we can see exactly what we are creating in 3D. This allows us to create the perfect fitting cover for your boat. After the cover is designed, we draw it out using our plotter. This draws out all the pieces of the pattern perfectly so our seamstress can sew it up!

This dingy cover was created out of Stamoid. Stamoid is a great material to make a boat cover out of. It is water, UV, and stain resistant. We used SolarFix thread in clear to sew this all together. Solarfix is a PTF thread which is also, UV, chemical, and mildew resistant. Which means, that you’d never have to bring your new dingy cover in for restitching after it’s been out in the sun for a few summers! Finally, on the bottom of the cover we did a draw cord. As a result, the cover can tighten around the dingy keeping the cover nice and secure, and your boat dry!

This dingy cover was created out of Stamoid. Stamoid is a great material to make a boat cover out of. It is water, UV, and stain resistant. We used SolarFix thread in clear to sew this all together. Solarfix is a PTF thread which is also, UV, chemical, and mildew resistant. Which means, that you’d never have to bring your new dingy cover in for restitching after it’s been out in the sun for a few summers! Finally, on the bottom of the cover we did a draw cord. As a result, the cover can tighten around the dingy keeping the cover nice and secure, and your boat dry!

Bertram 30′ Custom Full Enclosure

For this refurbished Bertram 30′ we created a custom full enclosure to keep this boat dry no matter what the weather has in store for you.

For this refurbished Bertram 30′ we created a custom full enclosure to keep this boat dry no matter what the weather has in store for you.

Here at Chicago Marine Canvas we use many labor-saving, cost-effective tools that help us speed up our process. We first go out to your boat to take precise measurements using our 3D measuring device. Then we head back to the shop and start our design process. We do all of our design work on the computer using CAD (Computer-Aided-Design) Software. Here we can visually see how the new enclosure will look, before we even begin the sewing process, that way we  can make any custom adjustments you want. After that, we send the design to our plotter, which is another one of or labor-saving tools, that quickly draws out all the pieces of your new enclosure. This saves our seamstress so much time while also making sure everything is precisely cut and drawn to the right size.

can make any custom adjustments you want. After that, we send the design to our plotter, which is another one of or labor-saving tools, that quickly draws out all the pieces of your new enclosure. This saves our seamstress so much time while also making sure everything is precisely cut and drawn to the right size.

For this enclosure, we used Stamoid fabric in white. Stamoid is UV, water, and fold resistant. It’s very easy to clean with just water! Check out this video to see Stamoids performance testing videos! For thread we used Solar Fix which is a PTFE or a  Polytetrafluoroethylene type of thread, which is also known as teflon, that is guaranteed for life! That means you can say goodbye to repairs that involve restitching. With this thread, your seams will last a lifetime! Solarfix doesn’t get eaten by the sunlight, salt water, or other outside elements. For the glass on this enclosure we used Strataglass. For some tips on how to clean strataglass to maintain its life check out this link.

Polytetrafluoroethylene type of thread, which is also known as teflon, that is guaranteed for life! That means you can say goodbye to repairs that involve restitching. With this thread, your seams will last a lifetime! Solarfix doesn’t get eaten by the sunlight, salt water, or other outside elements. For the glass on this enclosure we used Strataglass. For some tips on how to clean strataglass to maintain its life check out this link.