Process of a Custom Canvas

The Process

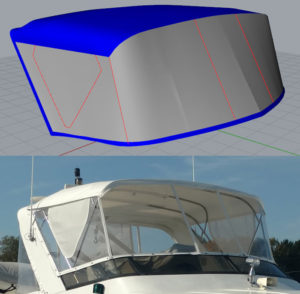

- After receiving all of the customers information, project details and deposit, we are able to start the process of creating their canvas. The first thing we do in our process is take measurements using our digitized canvas measuring system. This measuring system is a quick and efficient way to make a template of the boat without needing the actual boat or old canvas at our shop.

- After measuring the boat, we use the measurements to create the digital template on the computer. From there we are then able to start cutting the fabrics using an automated fabric cutting table. Once the fabric is cut the seamstresses get to work sewing it all together, and the hardware is added.

- Now that the project is complete our team installs the canvas onto the boat. If necessary, the canvas may be brought back for minor adjustments. It’s as simple as that!

DIGITAL MEASURING

Chicago Marine Canvas uses the most advanced measuring and manufacturing processes available to the industry today. Our digitized canvas measuring process uses laser technology that gives us pinpoint accurate dimensions. Which then translates to a 3D template of your boat and new cover.

This not only gives you a perfectly tight boat canvas, but it also reduces our manufacturing time by up to 80% which saves you money.

We have used this process for full enclosures, cockpit covers, framing upholstery (new and reupholster), eisenglass window replacement, carpeting and much more. Please view at some recent projects we’ve worked on to see the results.

Cruisers Yachts Full Bridge Enclosure and Aft Panels

On this Cruisers Yachts 3950 Aft Cabin we made a full bridge enclosure and aft panels. This project was made using Strataglass for the windows and Black Sunbrella Marine Fabric. Also, we made sure to design this enclosure with maximum visibility.

The project has a variety of different Strataglass windows including rollup windows and door panels. Throughout the project we used SolarFix thread. SolarFix thread is specifically made to be resistant to harmful UV rays and weathering. SolarFix thread also comes with a lifetime guarantee.

Rigid enclosures are made from a flexible glass like material, Strataglass, that provides clarity to your enclosure. There are different types of material thickness. Which allows for some windows to be rolled up, and other types to remain more glass like.

These enclosures are flexible to meet the shape of the boat. And can also store flat when not in use. Rigid enclosures are made high quality and can protect from 98% of harmful UV rays.

Strataglass is known for their flexible marine enclosure windows. The windows are highly durable and contain a scratch resistant coating. It should have a lifetime of 2-5 years when properly cleaned and used with the protective polish and protective cleaner.

Sunbrella is known for having high quality worry-free fabric. The fabrics are durable and perfect for indoor and outdoor projects. Sunbrella fabrics are resistant to abrasions, weather, mold and mildew.

Sunbrella has won many awards for their fabric designs. They offer hundreds of colors, and a wide range of patterns. While the fabrics are comfortable and durable, they are also very easy to clean.

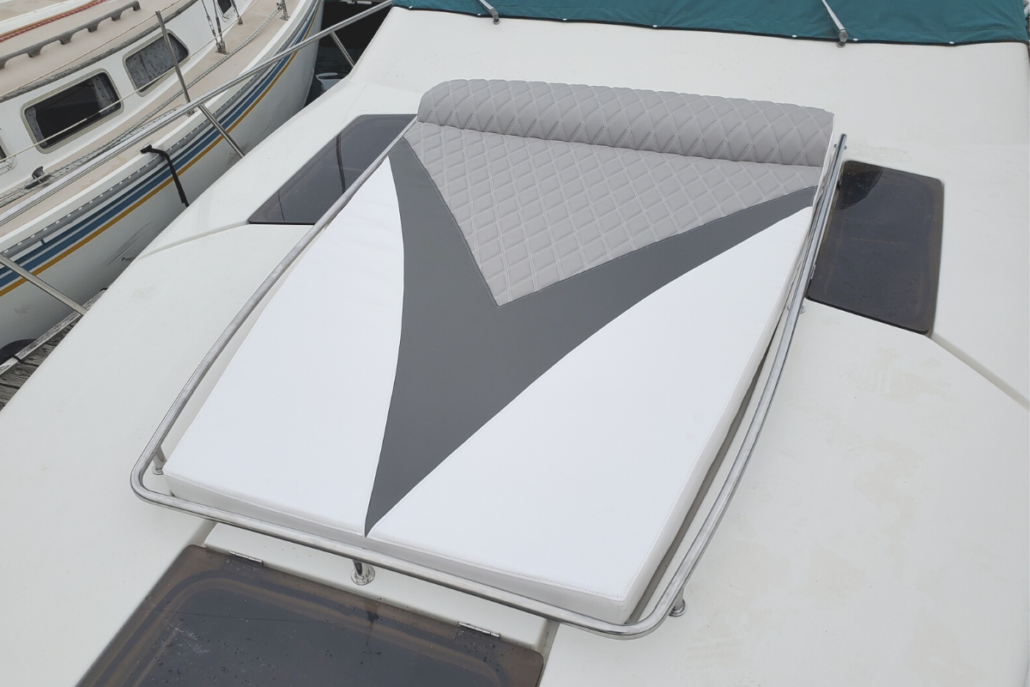

Double Sunpads – Sea Ray Sundancer 420

On this 2005 Sea Ray Sundancer 420 we made double sunpads using Cabana Classic Sunbrella upholstery fabric.

Sunbrella fabrics are highly durable and resistant to abrasions, weather, mold and mildew. And all Sunbrella fabrics come with a 5-year warranty.

Check out our page here to learn more about how to keep your fabric looking new and the cleaning process.

These sun pads have built in headrests help with max comfort while relaxing. Sunpads are made with 3″ tampered foam, whereas the head rests are elevated to 6″.

Cup holders and pockets were added onto the headrest to keep valuables in place when relaxing.

It was also made with Dri-Fast Foam that causes it to dry very fast. Since Drifast foam is a firm open celled foam that is very porous, it allows water to run through it easily, instead of absorbing it like other closed cell foams.

Our Marine Fabricator Magazine Article

Recently, we got the privilege to be published in the Marine Fabricator Magazine about our new shop space!

“Adjusting to a Bigger Shop” discusses the challenges and benefits we faced when transitioning to a larger workspace here at Chicago Marine Canvas. Emphasizing the importance of planning and organizing when expanding, we had some considerations to think about. Workflow optimization, equipment upgrades, and employee training, all had to be thought of. When upgrading the number of floors, we are also upgrading our productivity too!

Click here to read it in full!

The magazine article highlights the real-life experiences of our fabricators who have successfully adjusted to a larger shop. Showcasing the positive impact it has on productivity, efficiency, and the ability to take on larger projects, our new shop has made many improvements. Ultimately, the article encourages other fabricators to carefully assess their needs and develop a strategic plan when transitioning to a bigger shop. It has led to significant growth opportunities for us and it can for you too!

Dodger, Bimini and Frame Adjustment

Our team recently undertook an exciting project to update the dodger on a Jeanneau Yacht, customized to meet the specific needs of our valued customer. Dodgers are undoubtedly a perfect addition to any boat, much like bimini tops, providing protection and enhancing the overall boating experience. In this case, we focused on increasing the height of the dodger to ensure optimal functionality and comfort for the customer.

One of the notable features of this updated dodger is its windows, which are crafted from a polycarbonate semi-rigid material. This choice offers several advantages, including exceptional clarity that allows for unobstructed views of the surrounding environment. Furthermore, the material’s impressive durability guarantees that it will withstand the challenges of marine environments, while also providing effective rain protection. With this dodger in place, the customer can confidently enjoy their time on the yacht, even in adverse weather conditions

In addition to the top-notch materials used for the windows, we pride ourselves on the quality of the entire dodger construction. The thread and fabric utilized in most of our projects are of the highest caliber, ensuring longevity and strength.

We encourage you to visit Montrose Harbor to see the impressive results of this dodger update. You’ll find this project to be a testament to our expertise and dedication to meeting and exceeding our customers’ expectations.

Dockside Decking and Infinity Carpeting

On this Cruisers Yacht we made correlating dockside decking and infinity carpeting.

Most places offer one service or the other, but here at Chicago Marine Canvas we offer both. By providing both we are able to make sure both the carpeting and decking perfectly match.

These floorings provide durability to protect your boat from external elements. These materials are waterproof and UV proof.

Dockside Decking is a polyethylene based; UV-resistant closed-cell PE/EVA foam product currently available in over 10 color patterns.

It’s a revolutionary non-skid marine flooring product designed for rugged marine environments.

It’s soft on your feet and provides excellent traction when wet or dry.

In addition to its good looks, Dockside Decking won’t absorb those troublesome liquids typically found on deck.

Such as motor oil, fish blood, red wine or beer! Lastly, it is easy to clean and is stain resistant.

Infinity Fabrics Luxury Woven Vinyl® is not only beautiful but it is very functional marine carpeting. It is featured in many 2015 boat models such as Brunswick Boat Group, Chaparral Boats, Cruiser Yachts, Marquis Yachts, Tiara Yachts, Tracker Marine, and many, many more…

Upgrading to Infinity Fabrics Luxury Woven Vinyl® carpeting has never been easier. We can pattern any boat’s interior or exterior and fit it with the carpeting via glue down, snaps or it can lay on its own. A common practice of boaters which current carpeting that fits well is having us cut the new carpeting based off the old. This not only saves you money but provides a great solution most of the time. There are new designs rolling out all the time and over 100 designs and patterns to choose from.

Quilted Sun Pad

This project was customized to perfectly fit the costumer’s boat and vision. For this sun pad we used Sunbrella Horizon fabric along with a quilted pattern. There are over 50 standard quilting patterns available to choose from.

This sun pad has built in headrests help with max comfort while relaxing. Sunpads are made with 3″ tampered foam, whereas the head rests are elevated to 6″. We also have custom foam cutting which is able to level the pads on a convex bow.

Sunpads can be made with either vinyl or upholstery fabrics. Both options offer many benefits. Sunbrella is known for having high quality worry-free fabric.

The fabrics are durable and perfect for indoor and outdoor projects. Sunbrella fabrics are resistant to abrasions, weather, mold and mildew.

Sunbrella has won many awards for their fabric designs. They offer hundreds of colors, and a wide range of patterns. While the fabrics are comfortable and durable, they are also very easy to clean.

Cockpit Upholstery – Full Boat

Exterior Upholstery

For this Sea Ray Sundancer we did a full boat of exterior upholstery. The cushions and chairs were made using Polari sand Dollar and Beluga Mocha fabrics. Along with ActiveFoam Vinyl.

A diamond pattern can be found throughout the pieces to add extra details.

Chicago Marine Canvas uses the best upholstery fabrics, vinyls and faux leathers. Which are all certified for marine use. All fabrics are not only comfortable but also highly durable.

The customer wanted Sea Ray embroidered onto different pieces. Since embroidery is fully custom, any words or logos can be embroidered.