Exterior Upholstery

Rigid Enclosure

Rinker Fiesta Vee 270

To protect the interior of your boat, it is important to have a waterproof cover. Here at Chicago Marine Canvas we do custom covers for every boat, because every boat is different and we want your cover to fit tight so there is no room for water leaks when a rain storm comes. This is a Rinker Fiesta Vee 270 and we fabricated a custom cover for it this summer.

To protect the interior of your boat, it is important to have a waterproof cover. Here at Chicago Marine Canvas we do custom covers for every boat, because every boat is different and we want your cover to fit tight so there is no room for water leaks when a rain storm comes. This is a Rinker Fiesta Vee 270 and we fabricated a custom cover for it this summer.

We start off our process by going out on site to the boat to take measurements. Here at Chicago Marine Canvas we have a lot of cost-effective, labor-saving tools that help cut your covers cost down while making sure it is the perfect fit! For measuring  we use a portable 3d measuring device. After we gather all the measurements needed we head back to the shop to start the design process. For this cover our designer made sure to make cut outs for all the framing on this boat, leaving it up to our seamstress to make individual boots for each pole, along with velcro straps to assure the cover isn’t going anywhere in these Chicago winds. After we do all of our design work we head over to our plotter which draws out all of the pieces of your cover we just finished up. This is another one of our labor-saving tools. Our plotter can quickly draw out all of our patterned pieces for your new cover, instead of us having to do it all by hand! After everything is drawn out, we hand it all over to our seamstress so she can begin her process. She starts off by cutting everything out and then looking at the pattern to figure out the best way to sew everything together. After that, she organizes all the pieces and gets to work.

we use a portable 3d measuring device. After we gather all the measurements needed we head back to the shop to start the design process. For this cover our designer made sure to make cut outs for all the framing on this boat, leaving it up to our seamstress to make individual boots for each pole, along with velcro straps to assure the cover isn’t going anywhere in these Chicago winds. After we do all of our design work we head over to our plotter which draws out all of the pieces of your cover we just finished up. This is another one of our labor-saving tools. Our plotter can quickly draw out all of our patterned pieces for your new cover, instead of us having to do it all by hand! After everything is drawn out, we hand it all over to our seamstress so she can begin her process. She starts off by cutting everything out and then looking at the pattern to figure out the best way to sew everything together. After that, she organizes all the pieces and gets to work.

For this cover we used Sunbrella fabric in the color doubonette tweed. We love using Sunbrella fabric! It is fade resistant and has a 10 year warranty! To sew everything together we used GORE tenara thread in black. GORE tenara is another favorite product of ours. It is UV, salt water, chemical and extreme weather resistant! It has a lifetime guarantee, which means, all of your seams will outlast your canvas! We also installed a Boat Vent II in the middle of this cover so that all water that hits it, runs off!

We used DOT snaps in burgundy to blend into this cover, as well as stay puts all along the back.

70′ Hatteras

Visiting Chicago from Florida for the summer. This 70′ Hatteras lost its bimini somewhere from Traverse City to Chicago. We got to create a custom bimini for this boat to help bring the shade back into these boaters lives!

Visiting Chicago from Florida for the summer. This 70′ Hatteras lost its bimini somewhere from Traverse City to Chicago. We got to create a custom bimini for this boat to help bring the shade back into these boaters lives!

Our first step when we get a job is going on site to take measurements. We bring our 3d measuring device which is labor-saving and cost-effective. It saves us time measuring which saves you money at the end of the day on your new custom cover. After we gather all of our measurements we need and take lots of detailed photos we head back to the shop. We do all of our design work on the computer so we can physically see what we are creating, as well as be super accurate. This helps save us trips when we go to fit the new cover onto your boat. After we do all the design work we then bring it over to our plotter. This is another one of our tools that is labor-saving.  Instead of us hand drawing out all of our designs, our plotter does it for us, quickly and efficiently. Then we hand all of our plotted fabric over to our seamstress, who cuts everything out and then starts the fabrication process.

Instead of us hand drawing out all of our designs, our plotter does it for us, quickly and efficiently. Then we hand all of our plotted fabric over to our seamstress, who cuts everything out and then starts the fabrication process.

For this 70′ Hatteras bimini cover we used Stamoid fabric in white. Stamoid is UV, water, and fold resistant. It’s very easy to clean with just water! Check out this video to see Stamoids performance testing videos! To sew this up we used GORE tenara thread in clear. GORE tenara UV, saltwater, chemical, and extreme weather resistant. It is backed by a lifetime guarantee. We used lenzip zippers which also have a lifetime guarantee.

We installed this cover on the day the Cubs won the world series! Go Cubs GO!

Mediterranean Mainship

This 1989 open Mediterranean Mainship was in need of some protection from the rain, so we created it a cockpit cover using some of our favorite products.

This 1989 open Mediterranean Mainship was in need of some protection from the rain, so we created it a cockpit cover using some of our favorite products.

We start out all of our projects by going on site to the boat. We bring out our special 3d device to take measurements. Our 3d measuring device is cost-effective and labor-saving. It saves us time taking measurements which in the end saves you money on your new cover! After we gather our measurements we need we head back to the shop. We upload all of our measurements we gathered and start working on the design process. We do all of our  design work on the computer, creating a 3d design so we can see what the end product will look like. This way we can make sure to make any adjustments, or special needs that your cover may need on there instead of making multiple trips out to your boat. In this case we knew where all the poles for the framing of this boat were located, so during the design process we made sure to include them. After we finish the design process, we bring the design to our plotter, which is also a labor-saving, cost-effective tool we use here at Chicago Marine Canvas. It helps us save time by drawing out the patterned pieces of your new cover quickly, instead of us having to do it by hand. Then we hand everything over to our seamstress, who cuts out all the pieces and starts sewing them together.

design work on the computer, creating a 3d design so we can see what the end product will look like. This way we can make sure to make any adjustments, or special needs that your cover may need on there instead of making multiple trips out to your boat. In this case we knew where all the poles for the framing of this boat were located, so during the design process we made sure to include them. After we finish the design process, we bring the design to our plotter, which is also a labor-saving, cost-effective tool we use here at Chicago Marine Canvas. It helps us save time by drawing out the patterned pieces of your new cover quickly, instead of us having to do it by hand. Then we hand everything over to our seamstress, who cuts out all the pieces and starts sewing them together.

For this Mediterranean Mainship we used Sunbrella canvas in black along with black Sunbrella binding. Sunbrella canvas is one of our favorite products to use to create a new boat canvas for our clientele. It is fade resistant and has a 10 year warranty. To sew everything together we used GORE tenara thread which is UV, chemical, saltwater and extreme weather resistant. It has a lifetime guarantee and is great for outdoor applications. This thread will outlast your canvas. Our designer made sure to include all the locations of where the framing poles were, so we could make boots that wrapped around each pole, helping prevent water leakage from getting to the interior of this boat. We created custom boots and flaps using Sunbrella and velcro so that the cover would be nice and secure onto the boat. We attached the cover using DOT snaps in black, attaching from the top of the windshield to the back of the boat. We also used Boat Vent II to help with water runoff as well as ventilation in the boat. while your cover is up.

For this Mediterranean Mainship we used Sunbrella canvas in black along with black Sunbrella binding. Sunbrella canvas is one of our favorite products to use to create a new boat canvas for our clientele. It is fade resistant and has a 10 year warranty. To sew everything together we used GORE tenara thread which is UV, chemical, saltwater and extreme weather resistant. It has a lifetime guarantee and is great for outdoor applications. This thread will outlast your canvas. Our designer made sure to include all the locations of where the framing poles were, so we could make boots that wrapped around each pole, helping prevent water leakage from getting to the interior of this boat. We created custom boots and flaps using Sunbrella and velcro so that the cover would be nice and secure onto the boat. We attached the cover using DOT snaps in black, attaching from the top of the windshield to the back of the boat. We also used Boat Vent II to help with water runoff as well as ventilation in the boat. while your cover is up.

Cockpit Covers

Cockpit covers are one of the most common types of boat covers used in the marine industry. These types of covers can be used on all types of powerboats and have different variations available.

Most extend from the top of the windshield toward the aft of the boat. Another option is to extend the cover over the windshield protecting the windshield and the dashboard area from constant direct sunlight. Have you ever seen a dashboard that faded out, an over the windshield cockpit cover would have helped postponed this fading.

Frequently the boat covers are connected with button snaps but there are also other variations of fasteners that can be used. Twist the Dot and Lift the Dot fasteners can be beneficial in specific situations where there is extreme tension on the canvas.

Multiple types of fabric can be used for the cover. Sunbrella is a popular option and has over 70 fabric options in marine grade canvas available. A complete list of available can be found here – Sunbrella Samples . WeatherMax has super high strength and durability combine with long-term color retention and is cost-effective fabric available for marine covers and tops. Both fabrics have outstanding durability, high water repellent and excellent breathability.

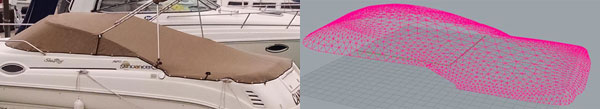

We measure all of our cockpit covers via 3D and build out the design in CAD software. This provides for a great fitting cover that will be enjoyed for years to come. Some of the pictures show the rendered design in a “Mesh” along with the finish product. Please contact us with any of your cockpit cover needs.