On Friday November 17, 2023, Marine Fabricators Association 2023 Regional Great Lakes Conference was hosted at Chicago Marine Canvas. Marine Fabricators Association members from across the country and different parts of the world including, New Zealand and Canada, traveled to the Windy City to be part of the two-day event being held at Chicago Marine Canvas. Fellow business owners, members of the MFA board, vendors, marine sewers and upholsters, and people wanting to learn more about the marine fabrication industry made up the list of attendees for the 2023 MFA Great Lakes Regional Workshop.

Everyone that attended this event did so for various reasons, maybe to learn something new, to network, to share business and product information, to exchange and expand their skills, or simply to be in the same space as like-minded business owners and partners. Regardless of the reasons, Chicago Marine Canvas worked hard to ensure that there was something for everyone to take home with them by covering topics like:

- Enclosures

- Shop Safety 101

- Shop Trucks

- Sewing Machine and Cutting Tables Demonstrations

- Upholstery

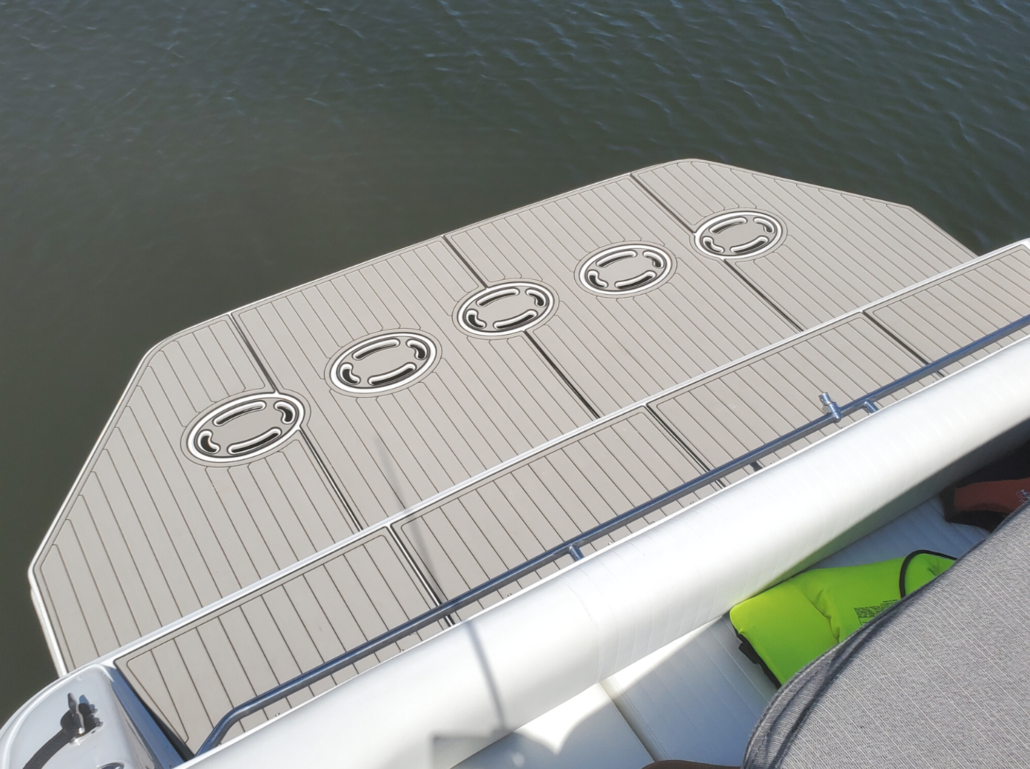

Enclosures

Using top of the line technology, Chicago Marine Canvas demonstrated how they take digital 3D patterns, design their covers in CAD software and fit their enclosures on a 1:1 scale frame. Not only that but they also fabricated windows from polycarbonate, pressed polished and rolled glass materials, discussing, and providing various examples of each one along the way. Chicago Marine Canvas showed their sewing processes and fitting of the bimini top with different types of window panels.

Shop Safety 101

We covered some common sense practices in the workplace, such as how work with sharp tools, equipment, potent chemicals, very loud noises, and other hazards, discussing the basic steps that every shop can take to ensure a safe workspace. One key takeaway from the Shop Safety 101 discussion that surprised many fellow marine fabrication business owners, was the discussion of ototoxicants, certain chemicals that may cause hearing loss through exposure. This goes to show that there’s always something essential to learn in the marine fabrication industry.

Shop Trucks

Chicago Marine Canvas partnered up with Steve Griffith from Marine Tops Unlimited to show off their two different shop trucks. All the attendees were able to learn some of the tricks of the trade that both Chicago Marine Canvas and Marine Tops Unlimited use while they are on the road. Some of these cool features include custom made storage and drawers that Chicago Marine Canvas installed in their shop truck to ensure that they always have a secure spot for all their tools and equipment while they are on the road.

On the other hand, Marine Tops Unlimited showed off their sewing machine along with the bits of fabrics and different kinds of thread that they keep on board for any quick and easy last-minute adjustments. Being able to see the different kinds of features from two different shop trucks, allowed the attendees of the MFA Great Lakes Regional Workshop to start thinking about how they too can start rolling in style by getting or modifying their shop trucks, in whichever way best meets their own marine fabrication industry needs when they are on the road.

Sewing Machine and Cutting Tables Demonstrations

By continuing with a hands-on-approach, Chicago Marine Canvas displayed how they use a variety of sewing machines such as straight stitch, double needle, long arm, embroidery, and many other specialty sewing machines as well. There were a few brave attendees that dared to try out an unfamiliar sewing machine for themselves and a few other lucky ones were able to snag a custom keychain made by one of the Chicago Marine Canvas team members.

Team members demonstrated their Prosail and Gerber automated fabric cutting tables which are used in their production process. The tables have the capability of not only cutting a variety of windows but also the polycarbonate, Strataglass and rolled eisenglass used on boat windows.

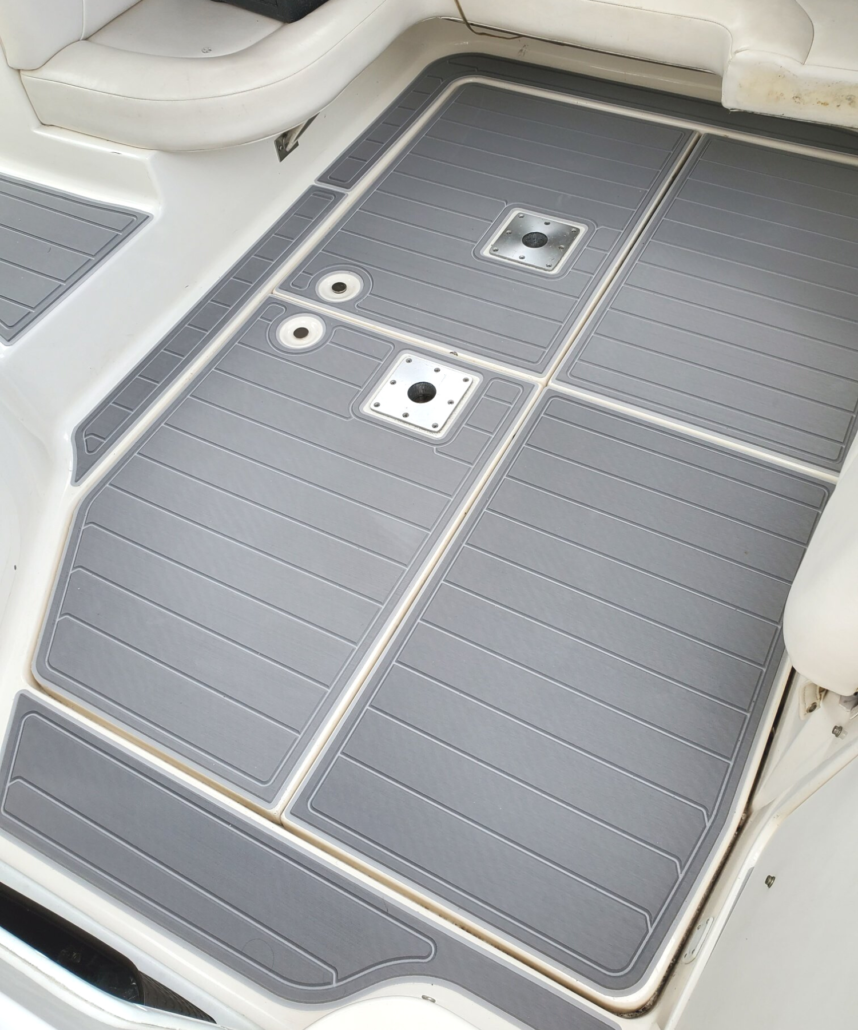

Upholstery

The conference concluded with an in depth look at the process of reupholstering seats on a Sea Ray Sundancer. Chicago Marine Canvas explained the steps taken to prepare, pattern and upholster some of the common seats found on cruiser style boats. One of the more time-consuming steps in the process is foam preparation which is the foundation of any upholstered piece. The group discussed the many different ways to achieve a great looking cushion at the end.

Special Thanks

Chicago Marine Canvas wants to thank all of those that attended. It was great to see old friends and make some new ones too! We look forward to collaborating with everyone at the national convention in January. This event wouldn’t have been possible without the help of the Chicago Marine Canvas team, the members of the MFA board, and everyone else who attended and made the 2023 MFA Great Lakes Regional Workshop a memorable one. Chicago Marine Canvas would like to extend a special thanks to all the vendors and sponsors of the event including:

- AP Consulting and Technical Services

- Continental

- Ennis Fabrics

- Fasnap

- Herculite Products Inc.

- Keyston Bros

- Marlen Textiles

- Miami Corporation

- Sattler Corp.

- Serge Ferrari Group

- Sunbrella

- Trivantage

- WeatherMAX Performance Fabrics

- Xtreme Seal