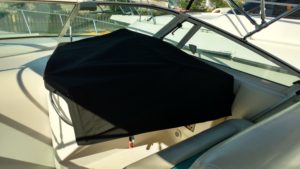

This Sundancer 300 was in need of a new full enclosure.

This Sundancer 300 was in need of a new full enclosure.

We always begin our process by going out to the boat with our team to take measurements. We use a 3d measuring device that is quick and efficient, which saves us time and you money at the end of the day. After we take the measurements, we head back to the shop to start the design process. We do all of our design work on the computer, making sure to custom tailor your new cover so that it fits perfectly. Once we finish up the design work, we have our plotter draw out all of the patterned pieces for this enclosure. Then we hand it over to our seamstress so they can get to work.

For this project we used Sunbrella in black, GORE tenara thread in black, and Sunbrella binding in black. GORE tenara thread has a lifetime warranty which means no more sun eaten seams. We also used Lenzip zippers in black which also have a life time guarantee.

For the front windows we used Makrolon which is a semi-rigid polycarbonate. The great thing about Makrolon is that it doesn’t sag like other vinyls. It also doesn’t expand or contract in different temperatures that way your cover always look brand new. With Makrolon your new enclosure looks like an extension off of your windshield, making your new cover looking super clean and chic.

The aft windows on this boat are Strataglass. We used large pieces of glass for maximum visibility. Strataglass is now the only vinyl on the market that comes with a 2 year warranty after install.

The aft windows on this boat are Strataglass. We used large pieces of glass for maximum visibility. Strataglass is now the only vinyl on the market that comes with a 2 year warranty after install.

We also created large canvas panels in the aft area of the boat, on the port and star side to help with shade while out on the water.