The Process

- After receiving all of the customers information, project details and deposit, we are able to start the process of creating their canvas. The first thing we do in our process is take measurements using our digitized canvas measuring system. This measuring system is a quick and efficient way to make a template of the boat without needing the actual boat or old canvas at our shop.

- After measuring the boat, we use the measurements to create the digital template on the computer. From there we are then able to start cutting the fabrics using an automated fabric cutting table. Once the fabric is cut the seamstresses get to work sewing it all together, and the hardware is added.

- Now that the project is complete our team installs the canvas onto the boat. If necessary, the canvas may be brought back for minor adjustments. It’s as simple as that!

DIGITAL MEASURING

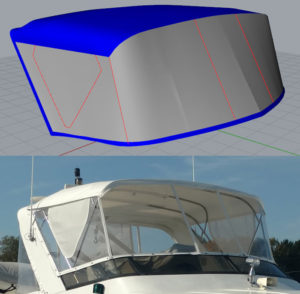

Chicago Marine Canvas uses the most advanced measuring and manufacturing processes available to the industry today. Our digitized canvas measuring process uses laser technology that gives us pinpoint accurate dimensions. Which then translates to a 3D template of your boat and new cover.

This not only gives you a perfectly tight boat canvas, but it also reduces our manufacturing time by up to 80% which saves you money.

We have used this process for full enclosures, cockpit covers, framing upholstery (new and reupholster), eisenglass window replacement, carpeting and much more. Please view at some recent projects we’ve worked on to see the results.